Quality doesn't just happen. Accurately assessing each machined part's risk before it hits production is a key way to improve quality. Taking a look at internal capability and comparing that to the type of material, part application and tolerance requirements takes experience and sound processes to yield the best results. Developing a script for each part and machine ensures that every operator knows the details of this analysis and not only sets up the machine accordingly, but follows strict protocols for quality checks during production.

First, it's important to look at your equipment and your operators to match the order with the right equipment and skilled labor. Also, looking at the application of the finished product is as important as looking at the type of material that is used. Finally, honing in on the features of the part that are the tightest tolerance will help prioritize quality checks. Experience helps when determining which features are most likely to give an operator trouble. Following the APQP Standards, define which features need to be checked and then determine the number and how often parts are to be monitored. Depending on the specification, an operator may only have to check a few times per shift or as often as every ten minutes. If, at any time, a part is out of specification make adjustments, but more importantly track the parts back to determine all that deviated from specification.

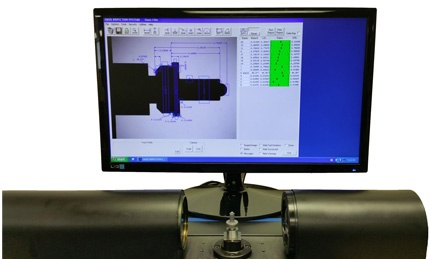

Quality doesn't stop there, however. After a part's run, a predetermined quantity of finished parts needs to be inspected. The lot size determines that quantity and should be checked 100%. Utilizing a variety of inspection methods and equipment like micrometers, pin and thread gauges, and Oasis optical inspection systems, inspectors need to test every element of a finished part, ensuring that it meets not only tolerance standards but surface quality and hardness.

Are you having quality problems with your parts supplier? Click below to get a quote for your project and see how PFI Precision Machining can solve your quality problem.