At PFI Precision Machining, manufacturing close-tolerance stainless steel components is one of our core strengths. Through our years of continued focus on process improvements and lean manufacturing techniques, we have developed an exceptional understanding of all of the factors that influence the quality, productivity, and consistency of machining stainless steel in all of its various grades and tempers.

Problem

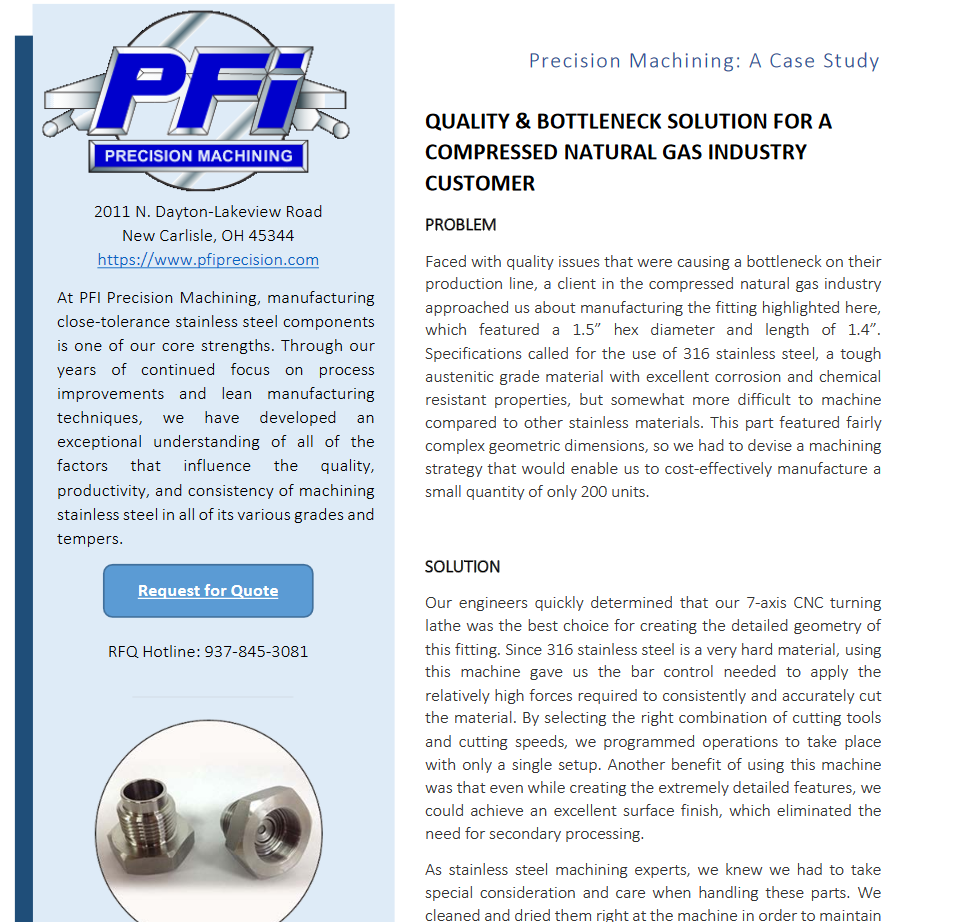

Faced with quality issues that were causing a bottleneck on their production line, a client in the compressed natural gas industry approached us about manufacturing the fitting highlighted here, which featured a 1.5” hex diameter and length of 1.4”. Specifications called for the use of 316 stainless steel, a tough austenitic grade material with excellent corrosion and chemical resistant properties, but somewhat more difficult to machine compared to other stainless materials. This part featured fairly complex geometric dimensions, so we had to devise a machining strategy that would enable us to cost-effectively manufacture a small quantity of only 200 units.

Solution

Our engineers quickly determined that our 7-axis CNC turning lathe was the best choice for creating the detailed geometry of this fitting. Since 316 stainless steel is a very hard material, using this machine gave us the bar control needed to apply the relatively high forces required to consistently and accurately cut the material. By selecting the right combination of cutting tools and cutting speeds, we programmed operations to take place with only a single setup. Another benefit of using this machine was that even while creating the extremely detailed features, we could achieve an excellent surface finish, which eliminated the need for secondary processing.

As stainless steel machining experts, we knew we had to take special consideration and care when handling these parts. We cleaned and dried them right at the machine in order to maintain part integrity, and properly packaged them to prevent damage during shipping. The client was very impressed with the quality of this difficult fitting. One of their worst problems was eliminated and they were able to catch up this part on their assembly lines. They appreciated not only our talent for producing parts of this high caliber, but also that we did it at a less expensive price than their supplier at the time.

Over half of our total production is stainless steel. To learn more about this project or our outstanding stainless steel machining capabilities, contact us today.